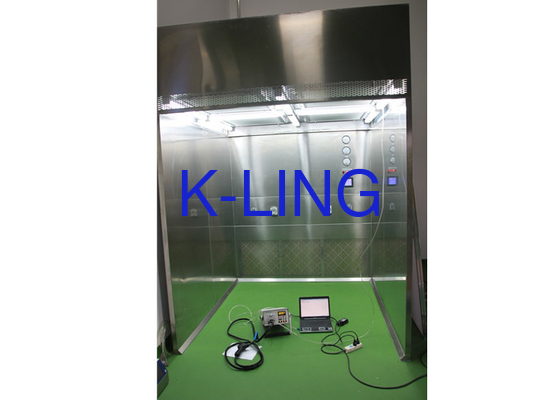

Construzione in acciaio inossidabile (SUS304) cabina di distribuzione con membrana di equalizzazione del flusso d'aria in polimero

Descrizione del prodotto

La cabina di distribuzione è un'apparecchiatura essenziale progettata per applicazioni di pesatura precise di polvere.Questa cabina ad alta tecnologia offre agli utenti un'esperienza user-friendly per un controllo ottimale e precisione.

Dotato di un potente ventilatore che funziona a 0,75 kW e compatibile con l'alimentazione a 380V/480V a 50/60HZ, questa cabina di distribuzione garantisce un'efficiente circolazione dell'aria all'interno dell'alloggiamento.Il funzionamento in tre fasi del ventilatore migliora l'affidabilità e le prestazioni, che lo rende ideale per il funzionamento continuo in ambienti industriali impegnativi.

Una delle caratteristiche chiave della cabina di distribuzione è la sua capacità di regolare la velocità dell'aria, fornendo un flusso d'aria costante di 0,45 m/s ± 20%.Questa funzione regolabile consente agli utenti di personalizzare la velocità dell'aria in base alle loro esigenze specifiche, garantendo un ambiente controllato per precisi processi di ponderazione della polvere.

Progettato per applicazioni di ponderazione della polvere, la cabina di somministrazione fornisce un ambiente pulito e controllato per misure accurate e somministrazione di polveri.Il suo grado di purificazione ISO5/Classe 100 garantisce un elevato livello di pulizia all'interno della cabina, che soddisfano gli standard di qualità e precisione del settore.

Sia che sia utilizzato in impianti farmaceutici, chimici o di ricerca,la cabina di distribuzione offre una soluzione affidabile per mantenere un ambiente sterile e controllato durante le procedure di ponderazione della polvereLe sue caratteristiche avanzate e la sua costruzione di qualità la rendono un'utilità preziosa per i laboratori e gli impianti produttivi che cercano di migliorare i loro processi di pesatura.

Caratteristiche

- Nome del prodotto:Stanza di distribuzione

- Nome:Stanza di distribuzione/stanza di campionamento

- Strada di pressione:Pressione negativa

- Lui:Schermata tattile

- Operazione:Automatica o semiautomatica

- Sistema di controllo:Sistema di controllo PLC

Parametri tecnici

| Parametro |

Specificità |

| Livello massimo |

Film di ammortizzazione o piastra di diffusione |

| Fase di filtrazione |

H14+F8+G4 |

| Velocità dell'aria |

0.45m/s ±20% regolabile |

| Operazione |

Automatica o semiautomatica |

| Filtro HEPA |

Mini-plegamento tipo H14 |

| Livello di rumore |

≤ 65 dB |

| Strada di pressione |

Pressione negativa |

| Porta |

Tela a strisce in PVC |

| Interfaccia HMI |

Schermata tattile |

| Nome |

Stanza di distribuzione/stanza di campionamento |

Applicazioni

Applicazione delle stanze di pesatura delle stanze pulite nella pesatura di materiali speciali per il settore aerospaziale

Il settore aerospaziale è spesso caratterizzato da materiali speciali, quali compositi ad alte prestazioni e propellenti per razzi, la cui pesatura deve essere effettuata in un ambiente pulito,rendendo essenziali le stanze di pesatura delle stanze pulite- i materiali compositi ad alte prestazioni sono utilizzati per la fabbricazione di componenti strutturali di veicoli spaziali e la precisione della pesatura influisce direttamente sulle prestazioni e sulla sicurezza dei componenti;attrezzature di alta precisione nelle sale di pesatura garantiscono proporzioni esatte della materia prima.

I propellenti per razzi sono infiammabili ed esplosivi e la progettazione a prova di esplosione e l'ambiente a pressione negativa della sala di pesatura impediscono incidenti di sicurezza causati da perdite di carburante,evitando allo stesso tempo la contaminazione che potrebbe compromettere le prestazioni di combustioneInoltre, la produzione di componenti per determinati strumenti di precisione utilizzati nell'aerospazio richiede che la pesatura del materiale venga effettuata in stanze di pesatura in camera bianca.garantire la qualità e l'affidabilità dei componenti, sostenendo così il successo delle missioni aerospaziali.

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!

Valutazione complessiva

Valutazione Istantanea

Di seguito è riportata la distribuzione di tutte le valutazioniTutte le recensioni